Smart IoT-Enabled Generators are transforming the power backup industry by integrating Internet of Things (IoT), artificial intelligence (AI), cloud platforms, and mobile connectivity into traditional diesel and gas generators. These technologies allow users to monitor, control, and predict generator performance remotely—dramatically reducing downtime, fuel waste, and maintenance costs.

In today’s data-driven world, remote generator monitoring has become essential for businesses, hospitals, telecom towers, factories, and data centers where uninterrupted power is mission-critical.

What Are Smart IoT-Enabled Generators?

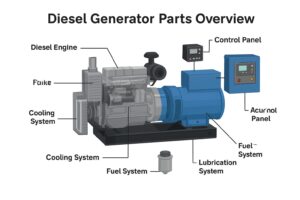

Smart IoT-Enabled Generators are power backup systems equipped with sensors, communication modules, and cloud software that continuously collect and transmit operational data.

Core IoT Components in Smart Generators

- Voltage, current, and frequency sensors

- Fuel level and fuel consumption sensors

- Engine temperature and oil pressure sensors

- GSM, Wi-Fi, or Ethernet connectivity

- Cloud dashboards and mobile apps

These components convert a conventional generator into an intelligent, connected asset capable of real-time decision-making.

How Remote Generator Monitoring Works

Remote monitoring is the backbone of Smart IoT-Enabled Generators.

Data Collection & Transmission

Sensors capture performance data and transmit it securely to cloud servers using cellular or internet networks.

Cloud Dashboards & Analytics

Operators can view:

- Live load percentage

- Fuel consumption trends

- Runtime hours

- Alarm history

- Maintenance schedules

This data is accessible anywhere through web portals or smartphone apps.

AI Predictive Maintenance in Smart Generators

One of the most powerful advantages of Smart IoT-Enabled Generators is AI-based predictive maintenance.

What Is Predictive Maintenance?

Unlike reactive or scheduled maintenance, AI analyzes historical and real-time data to predict failures before they happen.

Examples of AI Predictions

- Detecting abnormal vibration patterns

- Predicting injector or turbocharger failure

- Identifying early signs of overheating

- Forecasting oil degradation

This approach reduces unplanned downtime by up to 40% and maintenance costs by 25–30%.

Smartphone Connectivity & Mobile Control

Smart IoT-Enabled Generators can be fully monitored using mobile applications.

What You Can Do from Your Phone

- Start or stop the generator remotely

- Receive instant fault notifications

- Track fuel usage and runtime

- Schedule service reminders

- Generate performance reports

This level of control is especially valuable for fleet operators managing multiple generators across different locations.

Cost Savings & Operational Efficiency

Fuel Cost Reduction

Remote monitoring identifies:

- Fuel theft

- Inefficient load usage

- Excessive idling

Reduced Downtime

Early alerts allow technicians to intervene before failures occur.

Lower Labor Costs

Fewer site visits are needed because diagnostics are done remotely.

Applications of Smart IoT-Enabled Generators

Smart IoT-Enabled Generators are widely used in:

- Hospitals and healthcare facilities

- Telecom towers and BTS sites

- Data centers and IT infrastructure

- Manufacturing plants

- Construction and mining operations

These industries rely on smart power backup systems to maintain uptime and compliance.

How Smart Generators Improve Sustainability

Lower Emissions

Optimized load management reduces fuel burn and carbon emissions.

Smart Load Sharing

IoT systems balance loads across multiple generators, increasing efficiency.

Integration with Hybrid & Renewable Systems

Modern Smart IoT-Enabled Generators can integrate with:

- Solar PV systems

- Battery energy storage systems (BESS)

- Grid-tied microgrids

This creates intelligent hybrid power solutions ideal for energy-conscious businesses.

Step-by-Step: How to Implement IoT Generator Monitoring

Step 1 – Install IoT Sensors & Controller

Attach certified IoT modules to engine and alternator systems.

Step 2 – Connect to Cloud Platform

Configure GSM/Wi-Fi connectivity and data encryption.

Step 3 – Set Alerts & Dashboards

Customize alarms, reports, and user access.

Step 4 – Train Operators

Ensure staff understands dashboards and alerts.

Challenges & Security Considerations

Cybersecurity

Use encrypted data transmission and role-based access.

Network Reliability

Ensure fallback communication methods (SMS alerts).

Future Trends in Smart Generator Technology

- AI-driven self-healing systems

- Blockchain-based energy auditing

- Autonomous generator fleets

- Carbon-optimized dispatch algorithms

Internal & External Resources

- Internal Link (Placeholder):

👉 View Smart Diesel Generator Products - External DoFollow Link (Placeholder):

👉 Learn more about Industrial IoT Standards

Conclusion

Smart IoT-Enabled Generators are no longer optional—they are the future of power backup. With remote monitoring, AI predictive maintenance, smartphone connectivity, and cloud intelligence, these systems drastically reduce costs, downtime, and operational risk.

Businesses that adopt smart power backup systems today gain a competitive advantage through reliability, efficiency, and data-driven decision-making.

📌 FAQ

FAQ 1: What is a Smart IoT-Enabled Generator?

A smart generator uses IoT sensors, cloud software, and AI to monitor and manage power systems remotely.

FAQ 2: How does remote generator monitoring save money?

It reduces fuel waste, prevents failures, minimizes downtime, and lowers maintenance costs.

FAQ 3: Can IoT generators be controlled via smartphone?

Yes, most smart generators offer mobile apps for monitoring, alerts, and remote control.

FAQ 4: Are Smart IoT-Enabled Generators secure?

Yes, when implemented with encrypted communication and proper cybersecurity protocols.