Diesel generator parts are the backbone of reliable power generation across industrial, commercial, and residential applications. Whether you operate standby generators for emergency backup or prime power generators for continuous operation, understanding diesel generator parts is critical for performance, efficiency, and long-term cost control.

In 2025, evolving emission standards, higher load expectations, and longer service intervals make the correct selection of generator spare parts more important than ever. This comprehensive guide explains every major diesel generator component, how it works, how it fails, and how to select the correct replacement parts with confidence.

Why Understanding Diesel Generator Parts Matters in 2025

Modern diesel generators are no longer simple mechanical machines. They integrate electronic controls, precision alternators, advanced fuel systems, and compliance-driven exhaust components. Selecting incorrect or low-quality diesel generator parts can lead to:

- Voltage instability

- Premature alternator failure

- Excessive fuel consumption

- Emission compliance violations

- Catastrophic engine damage

Businesses that maintain deep knowledge of diesel generator parts consistently achieve longer generator life, lower downtime, and improved ROI.

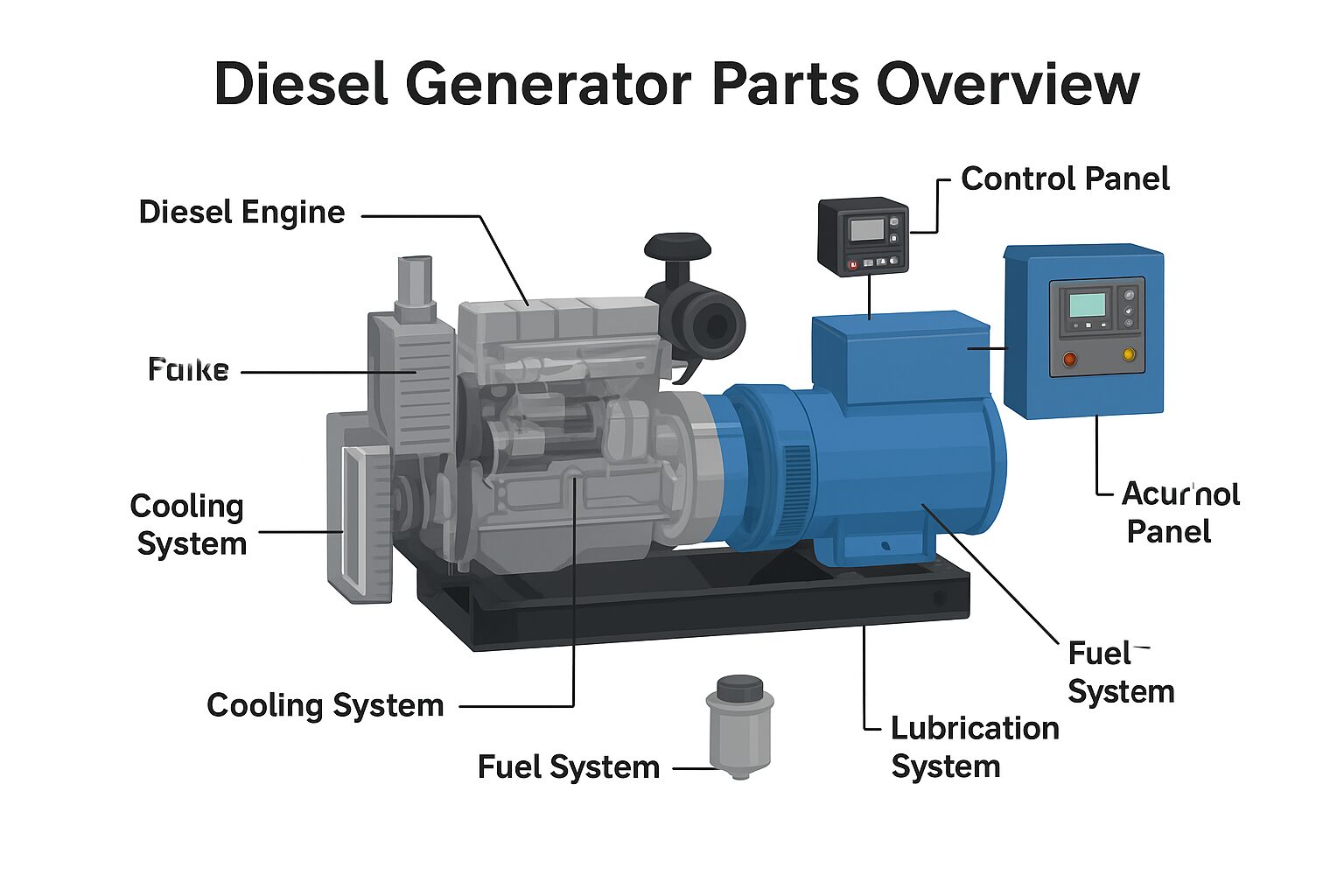

Core Diesel Generator Parts and Their Functions

Diesel Engine – The Prime Mover

The diesel engine converts chemical energy into mechanical power. Core engine-related diesel generator parts include:

- Cylinder block

- Pistons and piston rings

- Crankshaft

- Camshaft

- Cylinder liners

- Valves and valve guides

High-quality generator spare parts at the engine level directly affect compression efficiency, oil consumption, and emissions.

Alternator Assembly

The alternator converts mechanical energy into electrical power. Key alternator parts include:

- Stator windings

- Rotor

- Bearings

- Excitation system

- Cooling fan

The alternator is one of the most failure-prone diesel generator parts due to heat, vibration, and electrical stress.

Automatic Voltage Regulator (AVR)

The AVR controls output voltage stability. Common AVR types include:

- SX460

- AS440

- MX321

- MX341

Faulty AVRs cause voltage fluctuation, damaging sensitive loads. Replacing the AVR with an OEM-equivalent unit is critical for system stability.

Fuel System Diesel Generator Parts

The fuel system ensures precise fuel delivery and combustion efficiency.

Fuel Injectors

Fuel injectors atomize diesel for clean combustion. Worn injectors result in:

- Black smoke

- Power loss

- Higher fuel consumption

Fuel Pumps

Fuel pumps maintain pressure consistency. Common generator spare parts include:

- Mechanical lift pumps

- High-pressure injection pumps

Proper fuel pump selection ensures stable engine RPM under load.

Fuel Filters

Fuel filters remove contaminants that damage injectors. Regular replacement is one of the most cost-effective maintenance actions.

Cooling System Generator Parts

Cooling system failures are a leading cause of generator downtime.

Radiator and Cooling Fans

Radiators dissipate heat from engine coolant. Dust-clogged radiators reduce efficiency and increase thermal stress.

Water Pumps and Thermostats

These diesel generator parts regulate coolant circulation and temperature stability.

Lubrication System Components

Oil Pump

The oil pump distributes lubrication to all moving parts.

H3: Oil Filters

Oil filters prevent metal debris from circulating through the engine. Regular oil filter replacement protects bearings and camshafts.

Electrical Control and Protection Parts

Generator Control Panels

Modern control panels integrate:

- Digital controllers

- Load monitoring

- Alarm systems

- Auto start/stop logic

Sensors and Safety Switches

Critical sensors include:

- Oil pressure sensors

- Coolant temperature sensors

- Overspeed switches

These diesel generator parts prevent catastrophic failures.

Exhaust and Emission Components

Environmental compliance is increasingly strict in 2025.

Exhaust Manifold and Muffler

These parts reduce noise and direct exhaust gases safely.

Emission Control Devices

Depending on region, generators may require:

- Catalytic converters

- DPF filters

Common Diesel Generator Parts That Fail First

Based on field data, the most commonly replaced generator spare parts are:

- AVR units

- Bearings

- Fuel filters

- Voltage sensors

- Cooling fans

Proactive replacement minimizes unplanned outages.

OEM vs Aftermarket Diesel Generator Parts

OEM Parts

- Guaranteed compatibility

- Higher cost

- Brand certification

High-Quality Aftermarket Parts

- Cost-effective

- Widely available

- Must meet ISO and IEC standards

Selecting trusted suppliers is essential.

How to Choose the Correct Diesel Generator Parts

Always verify:

- Generator model

- Alternator serial number

- Voltage and frequency

- Load classification

- Emission requirements

Incorrect part selection is the leading cause of premature generator failure.

Maintenance Strategy Using the Right Generator Spare Parts

Preventive maintenance schedules should include:

- Air, fuel, and oil filter replacement

- AVR voltage checks

- Bearing inspection

- Cooling system flushing

You can reference a detailed maintenance checklist here:

Industry Standards Governing Diesel Generator Parts

Quality generator spare parts comply with:

- ISO 8528

- IEC 60034

- EPA Tier regulations

- EU Stage V standards

For official standards documentation, refer to:

[External Link Placeholder – International Generator Standards Resource]

Future Trends in Diesel Generator Parts

Emerging trends include:

- Smart AVRs with remote monitoring

- Low-loss alternator windings

- Extended-life bearings

- AI-based predictive maintenance

Suppliers who adapt early gain market leadership.

Why GeneratorPartsHub.com Is Positioned as an Authority

By offering:

- Verified diesel generator parts

- Technical compatibility guidance

- Maintenance documentation

- OEM-equivalent alternatives

GeneratorPartsHub.com strengthens trust, conversions, and long-term authority in the generator industry.

Conclusion

Understanding diesel generator parts is no longer optional—it is essential. From alternator parts and AVRs to filters and sensors, every component directly affects reliability and compliance. Businesses that invest in correct generator spare parts reduce downtime, lower operating costs, and extend generator life well beyond manufacturer estimates.

As power reliability demands increase globally, authoritative knowledge combined with quality parts sourcing will define industry leaders in 2025 and beyond.