Discover the 5 most common Kirloskar Generator Problems and learn how to fix them effectively. This expert guide explains causes, solutions, and maintenance tips to keep your Kirloskar generator running smoothly and reliably.

To fix issues you can contact us at.

Common Kirloskar Generator Problems and Their Causes

Even the most trusted Kirloskar generators can experience issues after heavy or long-term use. Understanding the common Kirloskar Generator Problems early helps prevent downtime and unnecessary repair costs.

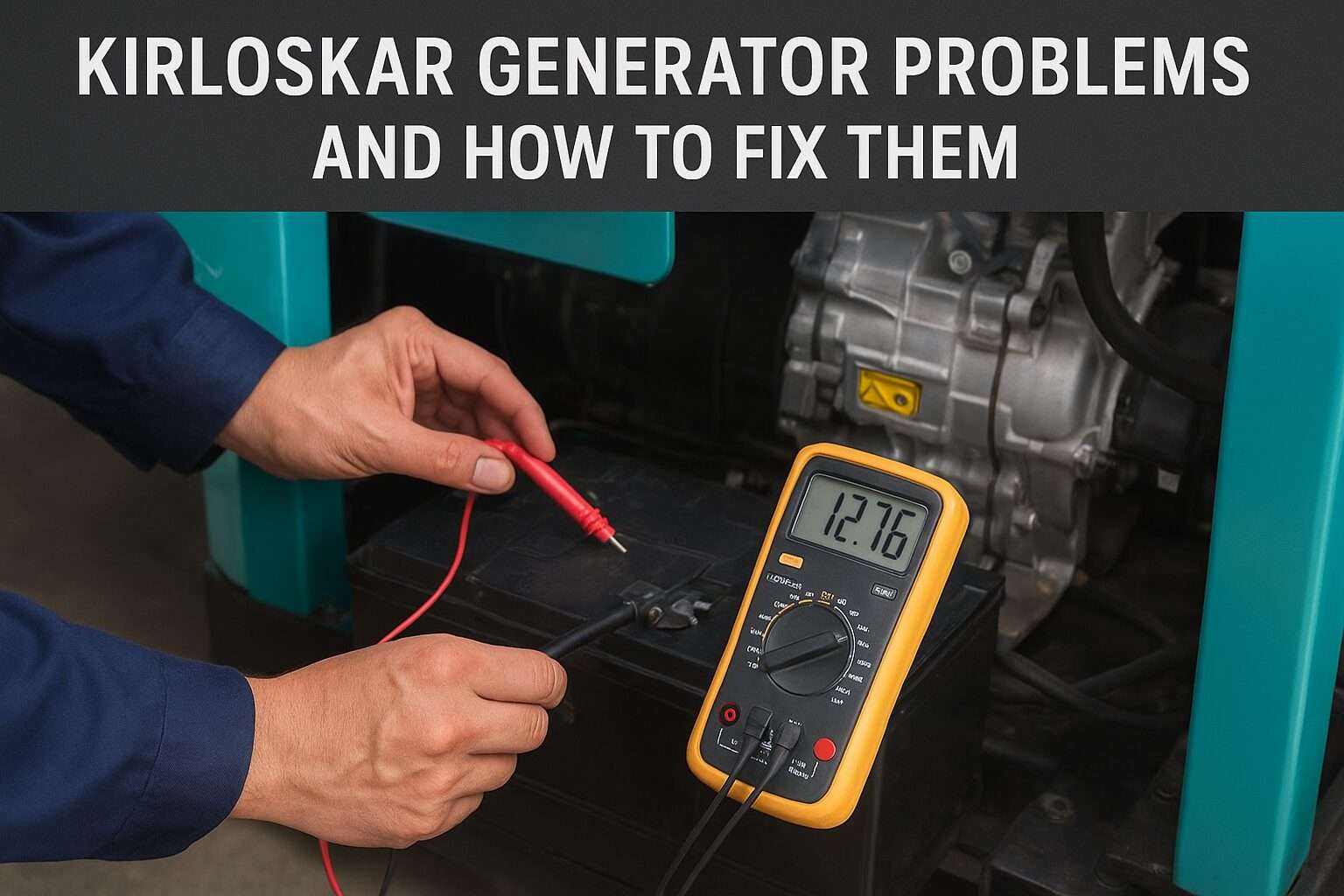

1. Starting Failure or Won’t Start

🔍 What Happens

In major Kirloskar generator issues the main problem is Your Kirloskar generator won’t crank or fails to build up power when you press start.

✅ Common Causes

- Dead or weak battery (or corroded terminals)

- Fuel system blockages or contaminated fuel

- Starter motor or solenoid malfunction

🧰 How to Fix It

- Test battery voltage (should be fully charged and healthy).

- Check connections and clean terminals.

- Drain, filter or replace fuel if contaminated.

- Inspect starter motor/solenoid for wear or failure.

Tip: Install a battery health-monitor and schedule start-ups regularly to avoid surprises.

2. Low or Unstable Output Voltage

🔍 What Happens

Second in Kirloskar generator issues is Generator seems to run, but voltage is too low, fluctuates, or drops under load.

✅ Common Causes

- Faulty Automatic Voltage Regulator (AVR) or alternator wear

- Improper engine speed (RPM) or load mismatch

- Internal wiring or connection issues in the alternator

🧰 How to Fix It

- Verify engine runs at correct rated speed for your model.

- Test/replace AVR fitted to your Kirloskar genset.

- Inspect slip-rings, brushes, and alternator windings for damage.

- Ensure load is within specs and that no sudden overloads occur.

Note: Always follow Kirloskar’s manual for alternator checks.

3. Overheating or High Engine Temperature

🔍 What Happens

3rd one in Kirloskar generator issues is Unit runs but overheats, or auto-shuts down due to thermal cut-off.

✅ Common Causes

- Cooling system issues (low coolant, blocked radiator)

- Fan belt loose or broken

- Operating under heavy load continuously beyond specs

🧰 How to Fix It

- Check and refill coolant to correct level; inspect for leaks.

- Clean radiator fins, ensure airflow is unobstructed.

- Check and adjust fan belt tension or replace if worn.

- Reduce load or break usage into safe intervals if necessary.

Reminder: Running beyond your genset’s rating shortens lifespan.

4. Excessive Smoke or Fuel Combustion Problems

🔍 What Happens

4th in Kirloskar generator issues is Black smoke, excessive fuel consumption, or smell of unburnt fuel.

✅ Common Causes

- Air intake filter clogged

- Poor fuel quality or wrong fuel injection timing

- Overloading or mismatch between load and generator capability

🧰 How to Fix It

- Replace or clean the air filter regularly.

- Use correct quality diesel fuel; drain water/contamination from tank.

- Inspect injector timing or call for professional servicing.

- Ensure load does not exceed rated capacity.

Pro Tip: Keeping your genset at 40–60% load helps maintain combustion efficiency.

5. Unexpected Shutdowns or Fault Codes

How to Fix Kirloskar Generator Problems Effectively

🔍 What Happens

5th one in Kirloskar generator issues is Generator shuts off unexpectedly or control panel shows fault codes.

✅ Common Causes

- Low oil pressure, high engine temp, or overspeed condition

- Electrical faults in control system or sensor failures

- Faulty wiring or broken ground connection

🧰 How to Fix It

- Check oil level and pressure; replace oil if needed.

- Review fault code in your Kirloskar control panel / manual.

- Inspect wiring harnesses, sensors, and ensure proper grounding.

- If faults persist, escalate to authorized technician for diagnostics.

Tip: Maintain a log of fault codes with dates for trending issues.

✅ Quick Reference Table

| Problem | Cause | Quick Fix |

|---|---|---|

| Won’t start | Battery/fuel/starter issues | Test battery, clean fuel, inspect starter |

| Low voltage | AVR/alternator or load mismatch | Replace AVR, inspect alternator |

| Overheating | Cooling system/overload | Clean radiator, check belts, reduce load |

| Excess smoke | Air/fuel/overload issues | Replace filter, check fuel quality |

| Unexpected shutdown | Oil/temp/controls fault | Check oil, read fault code, inspect wiring |

Preventing Future Kirloskar Generator Problems with Regular Maintenance

To minimize breakdowns, follow a routine maintenance plan for your Kirloskar generator. Schedule professional servicing every 250 hours of operation or at least twice a year. Regular inspections of filters, belts, fuel lines, and coolant systems can drastically reduce the chances of major failures.

For best results:

- Use genuine Kirloskar spare parts

- Keep the generator clean and dry

- Record all maintenance activities in a service log

Proactive care not only prevents future problems but also improves fuel efficiency and extends generator life.

Conclusion: Keep Your Kirloskar Generator Running Strong

Kirloskar generators are built for durability and power, but consistent maintenance is the key to long-term reliability. By understanding these common Kirloskar generator problems and applying the fixes shared above, you can ensure your power source stays dependable for years to come. For expert help, spare parts, or maintenance kits, visit GeneratorPartsHub — your trusted source for all generator needs.

To know more you can visit here.